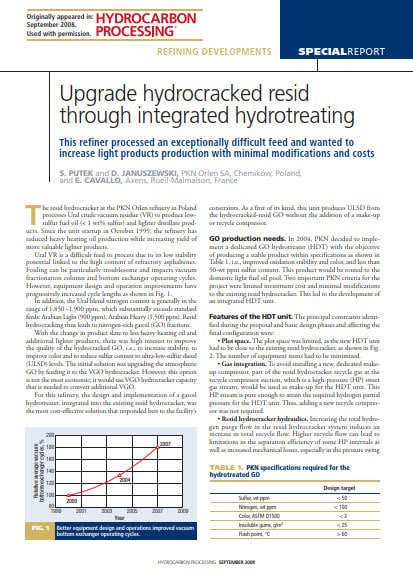

The resid hydrocracker at the PKN Orlen refinery in Poland processes Ural crude vacuum residue (VR) to produce lowsulfur fuel oil (< 1 wt% sulfur) and lighter distillate products. Since the unit startup in October 1999, the refinery has reduced heavy heating oil production while increasing yield of more valuable lighter products.