Part 1 of this article discussed how catalytic reforming processes produce olefin contaminants in aromatics streams via paraffin dehydrogenation side reactions.

Operating catalytic reformers at higher severity results in higher yields of valuable aromatics, but it also results in higher olefins content in the reformate.

Olefins must be removed from C6–C7 aromatics streams to meet benzene product specifications, and from C8+ aromatics streams to meet specifications for paraxylene recovery processes.

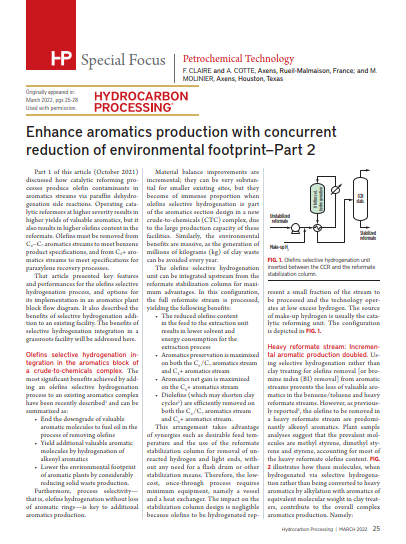

That article presented key features and performances for the olefins selective hydrogenation process, and options for its implementation in an aromatics plant block flow diagram. It also described the benefits of selective hydrogenation addition to an existing facility. The benefits of selective hydrogenation integration in a grassroots facility will be addressed here.

Catalytic reforming processes produce olefin contaminants in aromatics streams via paraffin dehydrogenation side reactions. Operating catalytic reformers at higher severity results in higher yields of valuable aromatics, but it also results in higher olefins content in the reformate.

Since the early 1940s, dual function catalysts have been converting lower octane, naphtha-range hydrocarbons into aromatics and higher octane blend stock for petrochemical and gasoline production while producing valuable hydrogen as a by-product.