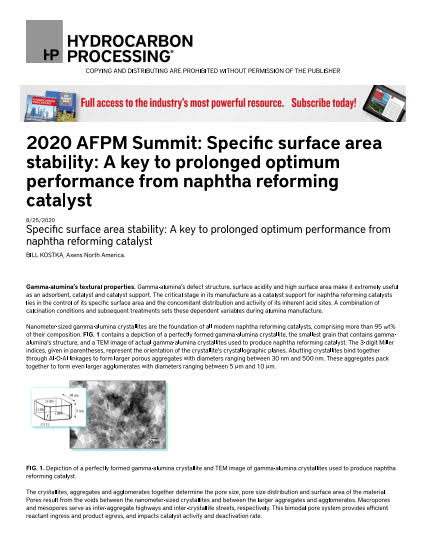

Gamma-alumina’s textural properties. Gamma-alumina’s defect structure, surface acidity and high surface area make it extremely useful as an adsorbent, catalyst and catalyst support. The critical stage in its manufacture as a catalyst support for naphtha reforming catalysts lies in the control of its specific surface area and the concomitant distribution and activity of its inherent acid sites.

A combination of calcination conditions and subsequent treatments sets these dependent variables during alumina manufacture.